-

Phone

86-532-85699925

-

Address

1408, Building 2, Noble Plaza, No. 328, Dunhua Road, Qingdao, Shandong, China

-

E-mail

LatestProducts

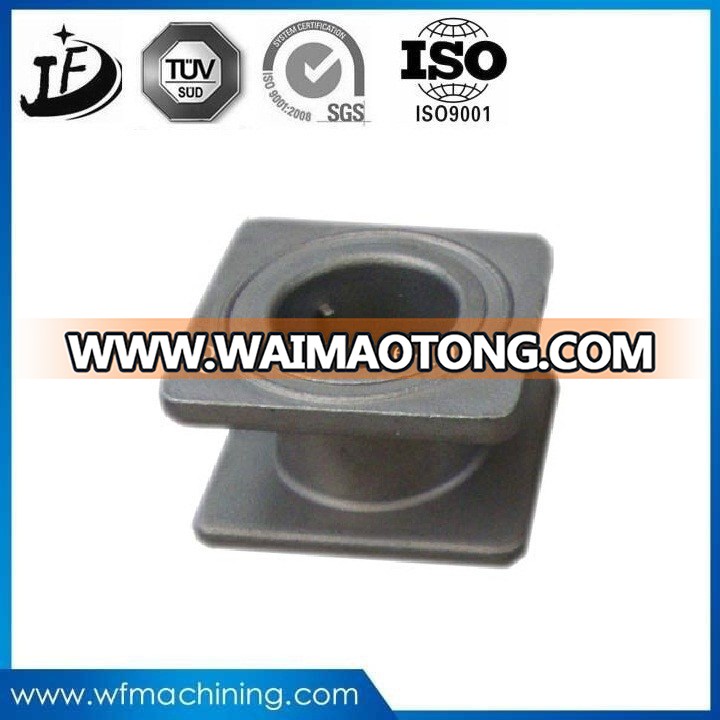

Custom Stainless Steel Investment Casting Part with CNC Machining

China Custom Stainless Steel Investment Casting Part with CNC Machining, Find details about China Cast Part, Investment Casting from Custom Stainless Steel Investment Casting Part with CNC Machining - Qingdao Donrex Co., Ltd.

Description

Basic Info

- Model NO.: ODM

- Deliver Time: 25-30 Days

- Transport Package: Bubble Bag, Carton, Pallets or Wooden Box

- Origin: China

- Material: Stainless Steel, Copper, Aluminum

- Trademark: ODM

- Specification: OEM

Product Description

Custom stainless steel investment casting part with CNC machining

Our company can supply various investment Casting Parts (OEM) according to the customers' drawings and requirements. Please offer us your enquiry with detailed drawings, specifications, unit weight, quality requirements and pictures. We will supply you not only the products with good quality but also competitive price and satisfactory service!

1. Material: Stainless steel , Steel, Aluminium alloy, Copper alloy and so on.

2. Process: Investment Casting.

3. Heat Treatment: Quenching, Tempering, Annealing, Normalizing, Nitridation, Carburization.

4. Surface Treatment: Zinc-Plated, Hot dipping galvanized, Polishing, Painting, Powder coating.

5. Machining Equipment: CNC Machines, Turning Machines,Drilling Machines , Milling Machines, Grinding Machines,etc.

6. Measuring Tool: CMM, Projector, Vernier Caliper, Depth Caliper, Micrometer, Pin Gauge, Thread Gauge, Height Gauge, etc.

7. Weight: 0.1-10kgs.

8. Application: Machinery Parts, Construction Industry, etc.

Bubble bag, carton, pallets or wooden box (As per customer's requirement).

Process:

The investment casting process is generally used for small castings. It is generally more expensive per unit than die casting or sand casting, but has lower equipment costs. It can produce complicated shapes that would be difficult or impossible with die casting, yet like that process, it requires little surface finishing and only minor machining.

Investment casting is used in the aerospace and power generation industries to produce turbine blades with complex shapes or cooling systems.Blades produced by investment casting can include single-crystal (SX), directionally solidified (DS), or conventional equiaxed blades.

Investment casting is also widely used by firearms manufacturers to fabricate firearm receivers, triggers, hammers, and other precision parts at low cost. Other industries that use standard investment-cast parts include military, medical, commercial and automotive.

We have two types of investment cast processes. They are the shell process (Colloidal Silica process) and the water glass process.

A wide range of alloys is available for both processes. They include carbon steels, low alloy steels, stainless steels, tool steels and copper based alloys. Please check the technical specification sheet for materials available.

Shell investment cast parts can range from a weight of just a few ounces to approximately 100 pounds-45Kg. Water glass castings may range in weight from several ounces to approximately 200 pounds-90Kg.

Casting tolerance can be controled within +-0.15mm.

First article layouts and spectrometer material certifications are provided with all first article samples.

A variety of secondary operations can be performed on both types of investment castings. They include heat treatment, machining, plating, painting, polishing and buffing, assembly services and even custom packaging.

Our service:

FAQ:

1. Can we get the samples?

Yes, we can supply you the samples for checking our quality within 10-30 days.

2. Can we place a trial order first time?

Yes, we are glad to supply you small trial order, and hope your quantity will be big in future.

3. Can you help us to do the customs clearance of import?

Yes, we can help you to do the customs clearance.

4. What is your lead-time?

With our design, fabrication and manufacturing skills and experience, we can efficiently exceed your expectations and meet the time frame required. However, we guarantee that quality and service are never compromised.

Our company can supply various investment Casting Parts (OEM) according to the customers' drawings and requirements. Please offer us your enquiry with detailed drawings, specifications, unit weight, quality requirements and pictures. We will supply you not only the products with good quality but also competitive price and satisfactory service!

1. Material: Stainless steel , Steel, Aluminium alloy, Copper alloy and so on.

2. Process: Investment Casting.

3. Heat Treatment: Quenching, Tempering, Annealing, Normalizing, Nitridation, Carburization.

4. Surface Treatment: Zinc-Plated, Hot dipping galvanized, Polishing, Painting, Powder coating.

5. Machining Equipment: CNC Machines, Turning Machines,Drilling Machines , Milling Machines, Grinding Machines,etc.

6. Measuring Tool: CMM, Projector, Vernier Caliper, Depth Caliper, Micrometer, Pin Gauge, Thread Gauge, Height Gauge, etc.

7. Weight: 0.1-10kgs.

8. Application: Machinery Parts, Construction Industry, etc.

Bubble bag, carton, pallets or wooden box (As per customer's requirement).

Process:

The investment casting process is generally used for small castings. It is generally more expensive per unit than die casting or sand casting, but has lower equipment costs. It can produce complicated shapes that would be difficult or impossible with die casting, yet like that process, it requires little surface finishing and only minor machining.

Investment casting is used in the aerospace and power generation industries to produce turbine blades with complex shapes or cooling systems.Blades produced by investment casting can include single-crystal (SX), directionally solidified (DS), or conventional equiaxed blades.

Investment casting is also widely used by firearms manufacturers to fabricate firearm receivers, triggers, hammers, and other precision parts at low cost. Other industries that use standard investment-cast parts include military, medical, commercial and automotive.

We have two types of investment cast processes. They are the shell process (Colloidal Silica process) and the water glass process.

A wide range of alloys is available for both processes. They include carbon steels, low alloy steels, stainless steels, tool steels and copper based alloys. Please check the technical specification sheet for materials available.

Shell investment cast parts can range from a weight of just a few ounces to approximately 100 pounds-45Kg. Water glass castings may range in weight from several ounces to approximately 200 pounds-90Kg.

Casting tolerance can be controled within +-0.15mm.

First article layouts and spectrometer material certifications are provided with all first article samples.

A variety of secondary operations can be performed on both types of investment castings. They include heat treatment, machining, plating, painting, polishing and buffing, assembly services and even custom packaging.

| Plain Carbon Cast Steel |

| Standard-Spec.No.& Grade | Chemical Composition≤% |

Mechanical Properties≥ | NOTE:(1)S,P≤0.04% (2)C,Mn%can also be agreed upon by manufacturer and purchaser. (3)Heat Treat:Normalize(N)+Temper(T) or Quench(Q)+T,selected by Foundry |

|||||||

| GB China |

JIS Japan |

ASTM U.S.A. |

C | Si | Mn | T.S. σb N/mm 2 |

Y.S. σs N/mm 2 |

EL δ% |

R.A. ψ% |

|

| ZG200-400 | SC420 | A27 60-30 | 0.2 | 0.5 | 0.8 | 400 | 200 | 25 | 40 | |

| ZG230-450 | SC450 | 65-35 | 0.3 | 0.9 | 450 | 230 | 22 | 32 | ||

| ZG270-500 | SC480 | 70-40 | 0.4 | 500 | 270 | 18 | 25 | |||

| ZG340-640 | SCC3B | A148 80-50 | 0.6 | 0.6 | 640 | 240 | 10 | 18 | ||

| High Alloy Cast Steel |

| Standard-Spec.No | Chemical Composition% | Mechanical Properties≥ | |||||||||

| GB China | JIS Japan | ASTM(AISI) U.S.A. | C | Si | Mn | Cr | Ni | Others | T.S. σb N/mm 2 |

Y.S. σs N/mm 2 |

EL σ% |

| ZG1Cr13 | SCSI | CA-15(410) | ≤0.15 | ≤1.50 | ≤1.00 | 11.5-14.0 | ≤1.00 | Mo≤0.05 | 620 | 450 | 16 |

| ZG0Cr18Ni9 | SCS13 | CF8(304) | ≤0.08 | ≤2.00 | ≤1.50 | 18.0-21.0 | 8.0-11.0 | 440 | 185 | 30 | |

| ZG1Cr18Ni9 | SCS12 | CF20(302) | ≤0.20 | ≤2.00 | ≤1.50 | 18.0-21.0 | 8.0-11.0 | 480 | 205 | 28 | |

| ZG0Cr18Ni12Mo2Ti | SUS316 | CF-8M(316) | ≤0.08 | ≤1.50 | ≤1.50 | 18.0-21.0 | 9.0-12.0 | Mo 2.0-3.0 Ti0.7 | 490 | 216 | 30 |

| ZG0Cr17Ni4Cu4Nb | SUS630 | CB-7Cu 17-4PH |

≤0.07 | ≤1.00 | ≤1.00 | 15.5-17.0 | 3.0-5.0 | Cu2.3-3.0 Nb0.14-0.45 | 980 | 785 | 5 |

| ZGMN13-3 | SCMnH2 | A128 B-1 | 0.90-1.30 | 0.30-0.80 | 11.0-14.0 | S≤0.05, P≤0.08 |

686 | 35 | |||

| ZG3Cr18Ni25Si2 | SCH19 | A297 HN | 0.20-0.50 | ≤2.00 | ≤2.00 | 19.0-23.0 | 23.0-27.0 | Mo≤0.50 | 435 | 230 | 8 |

| ZG4Cr25Ni20Si2 | SCH22 | A351 HK-40 |

0.35-0.45 | ≤1.75 | ≤1.50 | 23.0-27.0 | 19.0-22.0 | 450 | 240 | 10 | |

| Note:S,P≤0.04% except 13%Mn Steel(ZGM13-3) |

| Copper-base Cast Alloy |

| Standard-Spec.No. | Chemical Composition% | Mechanical Properties≥ | |||||||||

| GB China | JIS Japan | ASTM U.S.A | Sn | Zn | Pb | Si | Cu | T.S.σb N/mm 2 |

Y.S. σ% |

EL HBW | Hard ness |

| ZCuSn5Pb5Zn5 | BC6 | C83600 | 4.0-6.0 | 4.0-6.0 | 4.0-6.0 | Balance | 200 | 90 | 13 | 60 | |

| ZCuSn10Zn2 | BC3 | C90500 | 9.0-11.0 | 1.0-3.0 | 240 | 120 | 12 | 70 | |||

| ZCuZn16Si4 | SZBC3 | C87800 | Balance | 2.5-4.5 | 79.5-81.0 | 390 | 20 | 100 | |||

| ZCuZn40Pb2 | C85700 | 0.5-2.5 | 58.0-63.0 | 220 | 120 | 15 | 80 | ||||

Our service:

| 1. 20 years of manufacturing success in China and exporting experience worldwide |

| 2.Global specialized producer of machined castings. |

| 3. We combine our own resources with some other well-developed factories to fulfill a wide range of contract manufacturing capabilities. Working with one source, saves time and money. |

| 4. Satisfied supplier of 7 big companies from North America and Europe. |

| 5. Low cost mold materials and focus on efficiency offer a cost effective solution to your metal component purchasing requirements. |

| 6. Normal lead times range from 1 to 6 weeks for fully-machined components. |

| 7. Strong capacity to help customers develop new projects. |

| 8. Our sales department is 24 hours available in order to help our customers solve problems quickly. |

FAQ:

1. Can we get the samples?

Yes, we can supply you the samples for checking our quality within 10-30 days.

2. Can we place a trial order first time?

Yes, we are glad to supply you small trial order, and hope your quantity will be big in future.

3. Can you help us to do the customs clearance of import?

Yes, we can help you to do the customs clearance.

4. What is your lead-time?

With our design, fabrication and manufacturing skills and experience, we can efficiently exceed your expectations and meet the time frame required. However, we guarantee that quality and service are never compromised.